Aluminum is known as one of the important and versatile materials used in various industries. One of the important uses of aluminum in the electronics and heating industry (thermal management) is its use in the production of aluminum heat sink profiles. Aluminum heat sink profiles are one of the most important elements in electronic and industrial thermal management. These profiles are mainly produced from aluminum and its alloys and are used as a key means of transferring heat from heating parts to air or cooler surfaces. In the following, we discuss the uses and benefits of aluminum heat sink profiles

What is aluminum heatsink profile?

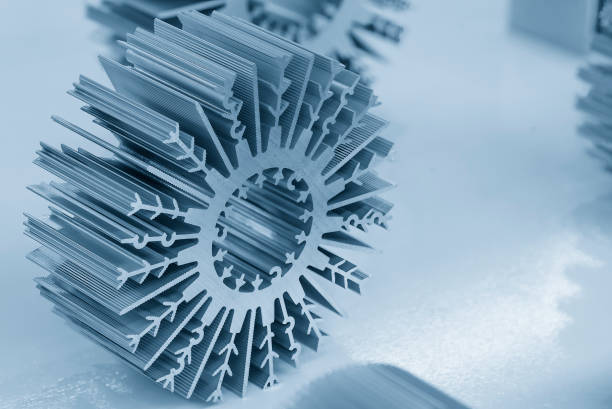

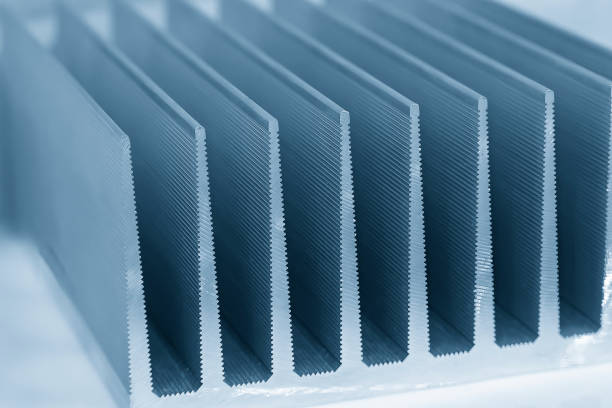

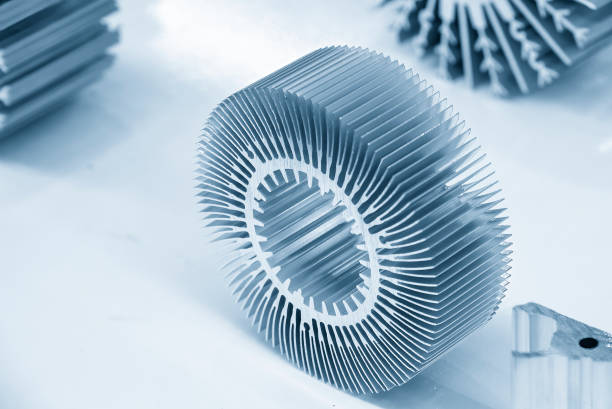

Aluminum heat sink profiles are aluminum products with a special shape that are used for better and optimal heat transfer in electronic and mechanical devices and systems. These profiles usually have external cooling surfaces (fins) and internal surfaces for connecting to heating parts. Aluminum heat sink profiles are aluminum products with a special shape that are used for better and optimal heat transfer in electronic and mechanical devices and systems. These profiles usually have external cooling surfaces (fins) and internal surfaces for connecting to thermal parts. Aluminum heat sink profiles are used as an important part in cooling systems, and their main task is to transfer heat from a thermal solution (usually electronic components) to a cooling solution (usually air or water). These profiles are made of aluminum because aluminum has good thermal properties and easily absorbs and transfers heat. Aluminum heat sink profiles are usually designed in different types, including flat profiles, strip profiles, channel profiles, etc., each of these types is suitable for its specific applications. The design of the fins and the surface structure of the profile is also determined based on the thermal and mechanical requirements to provide the best thermal efficiency. In general, heat sink aluminum profiles are used as one of the basic components in a large number of electronic and mechanical devices and equipment to prevent the increase in temperature and the possibility of damage to the thermal parts and to increase the useful life of the devices.

Applications of aluminum heat sink profile:

Applications of aluminum heat sink profiles are very important and extensive in the electronics industry. These profiles act as one of the key elements in the heat management of devices and electronic components. Here are some important points about the applications of aluminum heat sink profiles in the industry

Effective cooling: the heat sink aluminum profile has an external structure in the form of fins (cooling edges) that help to increase the contact surface with air and increase heat transfer. This structure of fins helps the heating parts to provide their heat effectively and transfer it quickly to the cooling environment. Protection of electronic components: As the power and performance of electronic components increase, heat production also increases. Using the aluminum heat sink profile as a thermal cover helps to prevent the temperature increase and the destruction of electronic components, this helps their useful life. Light and resistant: Aluminum is known as a light material with good resistance to heat and rust. These features make aluminum heatsink profiles very suitable for use in portable equipment and devices that use light weight. Multipurpose design: Aluminum heat sink profiles can be easily adjusted to different designs. This possibility allows engineers to adjust the profiles to the shape and size they need

Electronic:

One of the main uses of aluminum profile is heat sink in the electronics industry. These profiles are installed on thermal components such as computer processors, transistors, and microcontrollers to effectively absorb the heat produced by these components and transfer them to the cooling environment. This application prevents the temperature increase and the destruction of electronic components.

Automobile industry:

Aluminum heat sink profiles also have important applications in the automobile industry. They are used for engine coolants, ABS brakes, and electronic devices in cars. Also, the light weight of aluminum helps to increase the fuel efficiency of cars.

aviation industry:

In airplanes, aluminum heatsink profile applications include engine cooling systems and airplane electronic components. Aluminum is used as a lightweight material with a long service life in harsh air environments.

Energy industry:

Aluminum heat sink profiles are also used in the energy industry. They are usually used in the production and transmission of thermal energy in power plants and energy production systems.

Electronic equipment at home:

Aluminum heatsink profiles are also used in home appliances, including televisions, personal computers, game consoles, and other devices. These profiles help to drain heat from electronic components and increase the useful life of these equipments.

Medical Equipment:

In medical equipment such as signaling devices, scanners, and diagnostic equipment, aluminum heat sink profiles are used for heat management to maintain the accuracy and efficiency of these equipments.

These examples of aluminum heat sink profile applications show that these products are used in various industries as a vital tool for heat management and increasing the useful life of electronic and mechanical parts.

Advanced materials and new technologies:

Advances in materials and technologies help improve the performance of aluminum heatsink profiles and provide new possibilities for engineers and manufacturers. Below are some of these improvements: Composite materials: Adding materials such as copper, resistance, or steel to aluminum can increase thermal efficiency. For example, aluminum with copper in the structure called “aluminum copper” can have better cooling and prevent deformation at high temperatures. Advanced production methods: Advanced production technologies such as laser engraving and precise turning have helped to produce aluminum heat sink profiles with high precision. These methods enable the production of fins and cooling structures that are more complex and optimized. More optimized design: Using optimization and thermal simulation engineering software, designers can design aluminum heatsink profiles with more optimized structures. This means improving their performance and thermal efficiency. Defect detection methods: new technologies are used in the field of defect detection, such as thermal imaging, to quickly detect and fix thermal problems and damages in the aluminum heat sink profile. Thermal radiation management: New methods of thermal radiation management have been introduced using special coatings and colors on the surfaces of profiles to help increase thermal radiation and reduce temperature. These developments have helped to improve the efficiency, resistance, and usability of aluminum heat sink profiles in many industries and applications, and they play the most important roles in heat management and stability of electronic and mechanical parts.

Environmental sustainability:

Challenges:

In addition to the advantages of aluminum heatsink profiles, there are also challenges that may be considered in using them. Some of these challenges are: Production costs: the production of heat sink aluminum profiles requires complex processes and high energy consumption. These things can lead to increased production costs, which may affect the final price of the product. The variable price of aluminum material: the price of aluminum as a material varies to a large extent and is affected by factors such as changes in the global market and supply of resources. This variability in price may affect producers’ planning and decisions. Accurate design: The design of the aluminum heat sink profile must be done carefully and according to the thermal requirements and the available space in the system. If the design is done incorrectly, the profiles may not be able to effectively transfer heat and improve device performance. Choosing the right material: sometimes choosing the right material for the heatsink aluminum profile can be challenging. Factors such as aluminum type, thickness, and addition of additional materials must be carefully considered. Impact resistance: Aluminum is sensitive to collisions and impacts, and challenges may arise in cases where the profiles are under pressure or impact. Nevertheless, with proper management and according to the specific needs of each project, aluminum heat sink profiles can be used as an effective tool in heat management and increasing the useful life of electronic and mechanical parts.

Final word:

In the end, aluminum heat sink profiles play a role as one of the symbols of technological progress in the heat management of our machines and electronic devices. With a combination of features such as lightness, high performance, and environmental sustainability, these products help to improve the quality and efficiency of modern life. Also, many improvements in the design and production technology of these profiles are expected to bring a brighter and better future for heat management in various industries. From aluminum to a hotter future, heatsink profiles are with us to equip modern machines and devices with excellent performance and thermal stability.